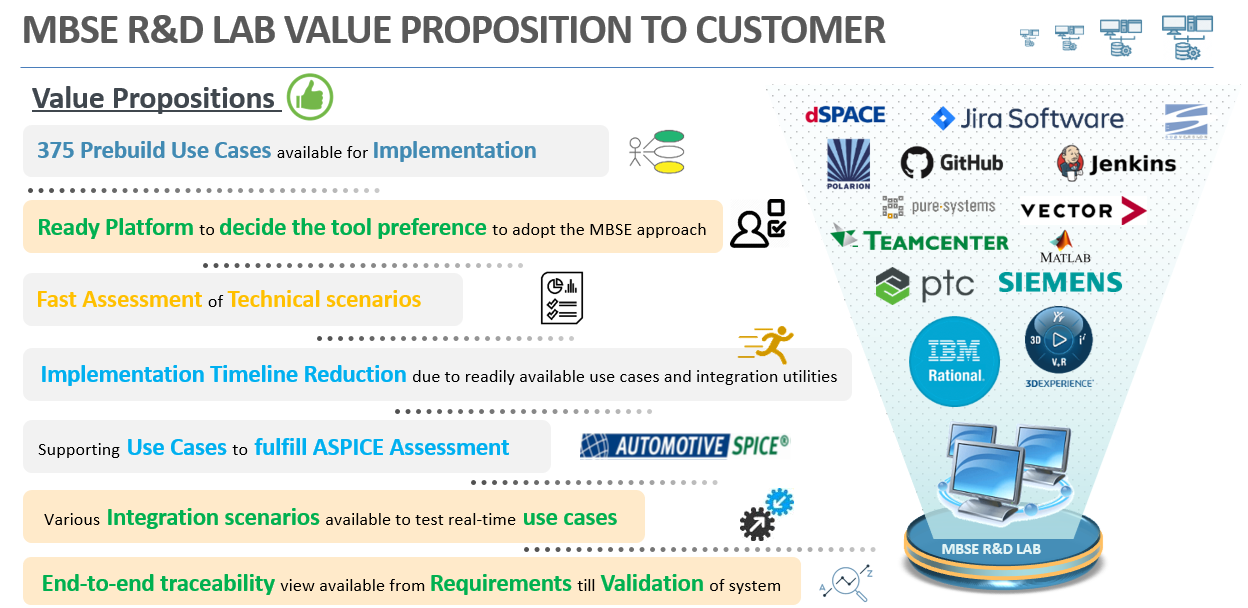

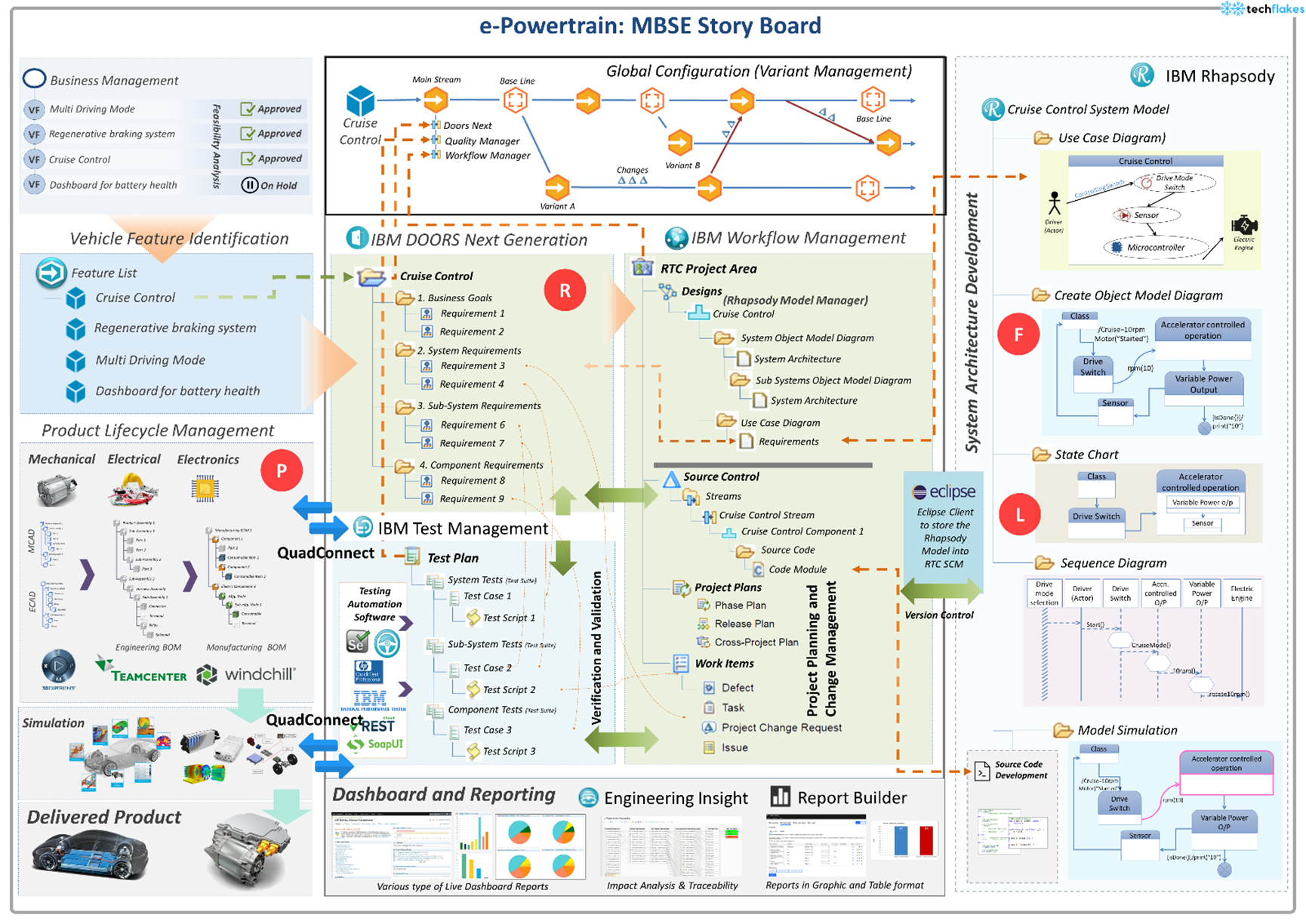

MBSE Lab

Model-Based Systems Engineering (MBSE) is the formalized application of modelling to support system requirements, design, analysis, verification, and validation activities beginning in the conceptual design phase and continuing throughout development and later life cycle phases.