Technology Consulting & Architecture

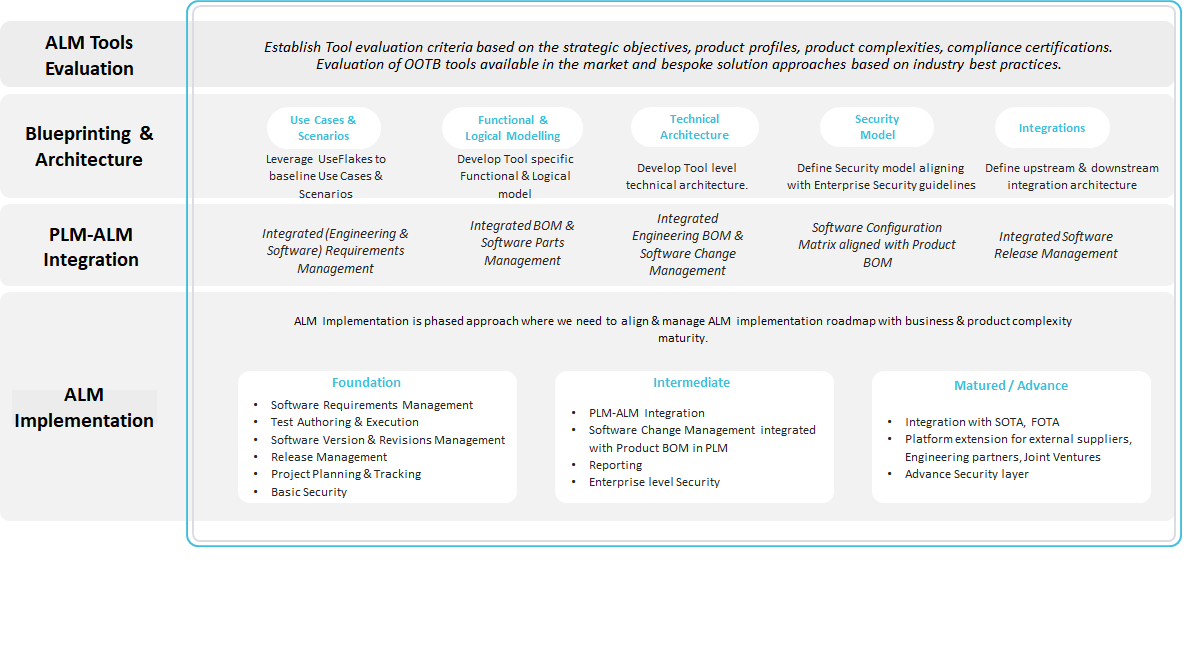

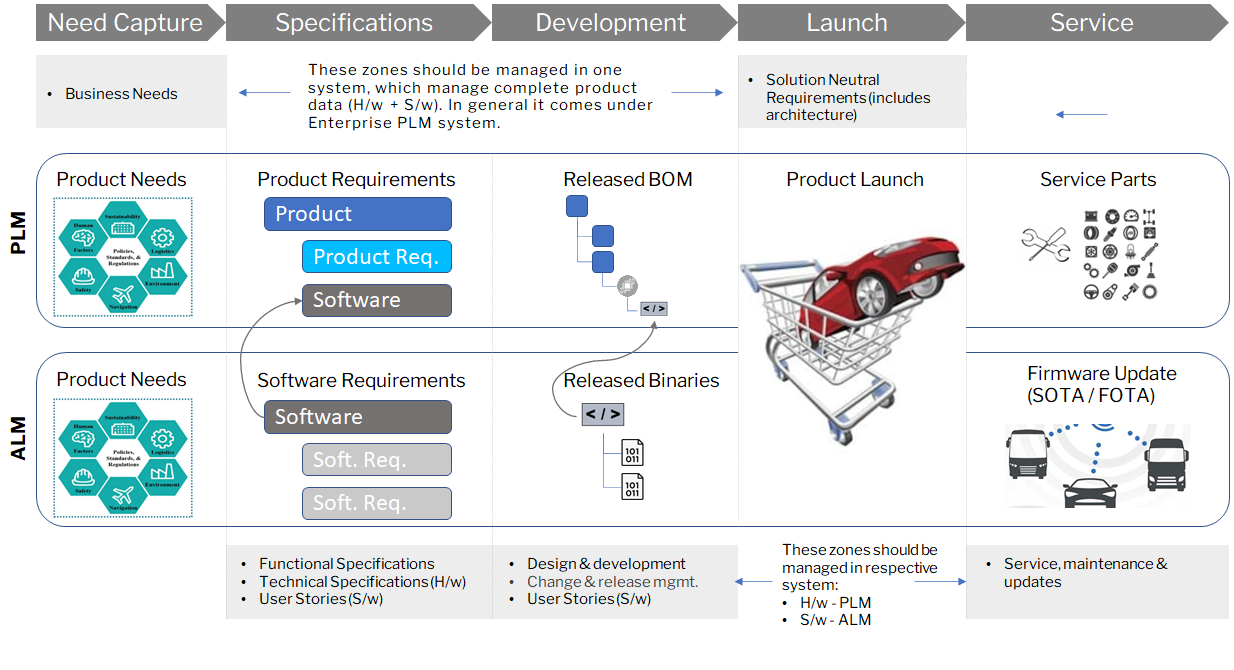

ALM implementation blueprint requires an alignment with capabilities required at various stages of the new product development cycle. Techflakes leverages our home grown UseFlakes product that gives configurable use cases across the NPI phases. We frequently experience the gap in communicating transition state & end state models of the overall ALM roadmap; Techflakes digital develops functional & logical model based on the use cases & scenarios. These early models help all stake holders to have common understanding of the capabilities & implementation roadmap.

Following functional & logical modelling we develop technical architectures, data models, security models, end to end data flows, technical requirements mapping with implementation phases. These technical artifacts bring clarity for the development team, improves quality of implementation, reduces feedback loops & rework.